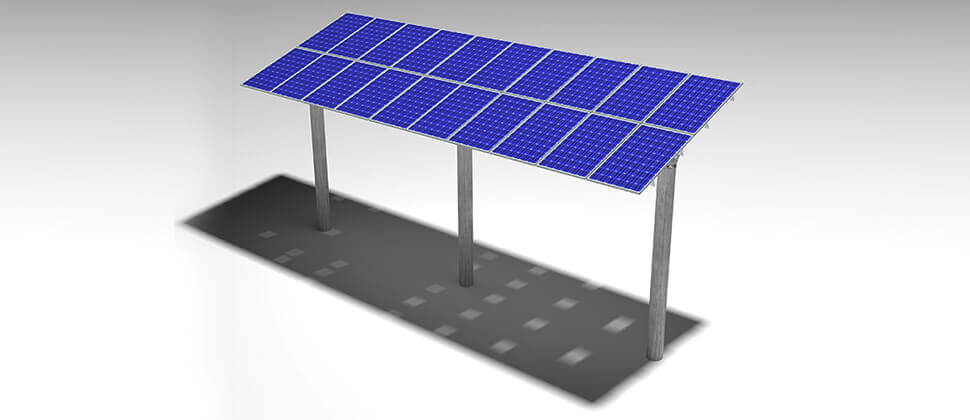

Single Pole Hat On C Structure

A seamless fusion of uniformity and customisation structure with a single pole. standardised to handle the convenience, speed, and suitability of manufacture and installation, and customised to incorporate every possible detail of the demand .The customization can be incorporated for module types ranging from 50Wp to 400Wp.

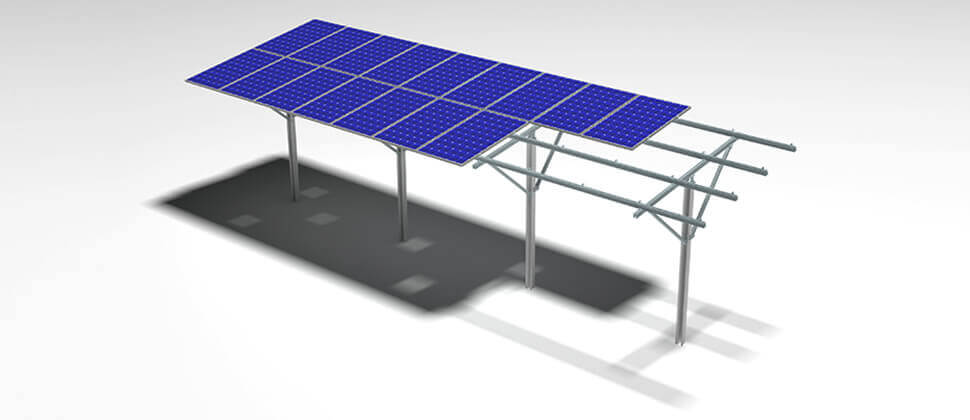

Single Pole Hat On Hat Structure

The design of a single pole hat on hat framework enables quicker production and simple on-site installation. It has a fairly straightforward design with specialised components and specific manufacturing and installation procedures. The design is suitable for all soil types, including rocky strata and sandy deserts.

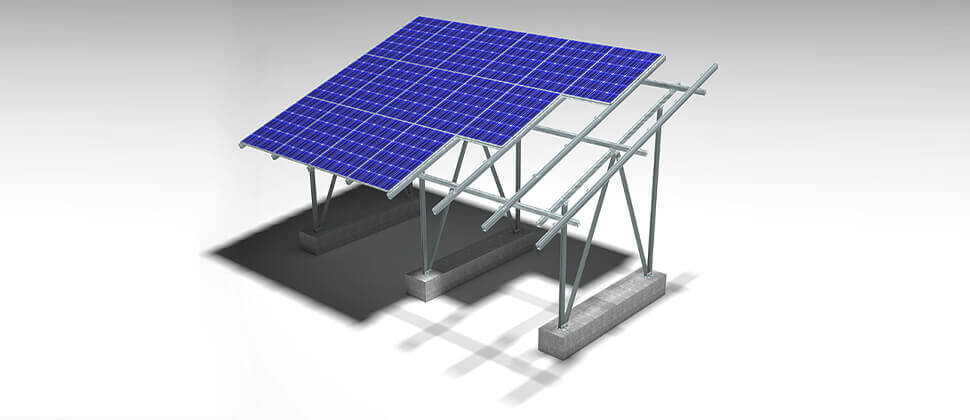

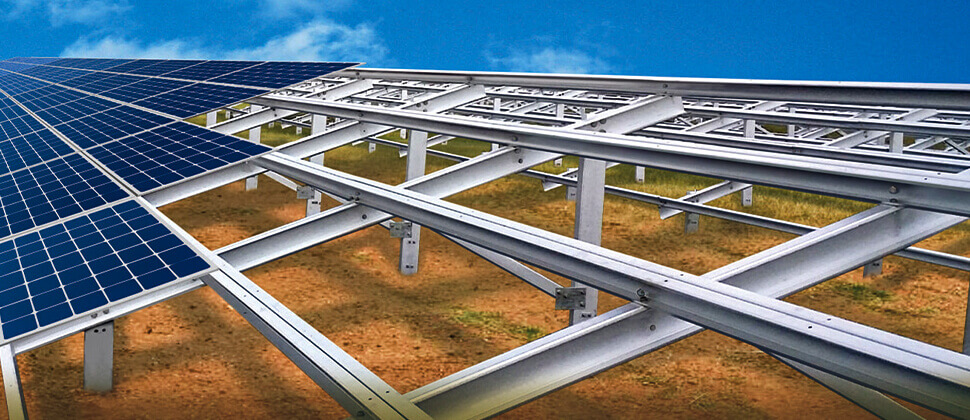

Dual Pole Landscape Orientation

The twin pole structures are the solar panel mounting structures supported in such unusual soil conditions. With an ideal array layout, the landscape orientation of twin pole structures can easily accommodate more than 200 modules per structure.

Seasonal Tilt Portrait Orientation

It is a low-cost alternative to tracker systems that enables tilt angle changes to maximise incident radiation and energy yield for the entire year. During the course of the year, the tilt (angle of inclination) of the adjustable solar panel mount can be modified two or more times, increasing the output of the panels as a whole by roughly 5%.

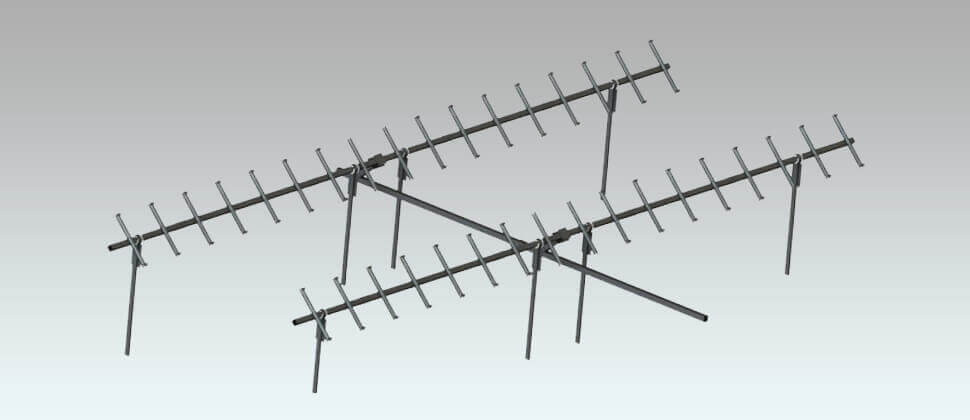

Trac

Tracking can become cost-effective. The three main characteristics for which these constructions are developed and created are durability, stability, and upkeep. The building is outfitted with cutting-edge safety features including wind-load sensors and is built to withstand unexpected wind loads from a variety of angles.

Low Elevation Ballast Structure

The wind shield systems' structures are especially created (in the form of an extended triangle) for flat roofs with constrained load capacities. On the back side, a sloping wind deflector closes the system and lessens the wind's suction force. The shield aids in preventing an even distribution of air flow, which results in strong three-dimensional flow patterns, as the wind blows through the gaps. The attached wind shield creates an aerodynamic effect that stabilises the system under heavy wind loads and stops the frame from lifting or tossing in the wind.

Elevated Ballast Structure

The solution is advised for flat RCC roofs with shading issues. The name of the structure solution is self-explanatory. These constructions can easily withstand wind loads brought on by winds up to 180 Kmph and can be built with ground clearance up to 1000 mm. They can be customised to fit 4 to 20 modules per structure in various array configurations. There is a 5 to 25 degree tilt range.

With Steel Rails

This structure blends in with the roof's architecture without detracting from the building's aesthetic appeal. The building's strength helps the L plate connection with the roof maintain its rigidity in the face of strong winds. This is the most dependable solution because to its good characteristics and low number of penetrations over the roof.

With Aluminium Rails

The next generation of the L plate + steel rail structure is L plate + Aluminum rail. Use of aluminium purlins drastically reduces the overall structure weight but maintaining the robustness intact.

Omega Clamp

The wind shield systems' structures are especially created (in the form of an extended triangle) for flat roofs with constrained load capacities. On the back side, a sloping wind deflector closes the system and lessens the wind's suction force. The shield aids in preventing an even distribution of air flow, which results in strong three-dimensional flow patterns, as the wind blows through the gaps. The attached wind shield creates an aerodynamic effect that stabilises the system under heavy wind loads and stops the frame from lifting or tossing in the wind.

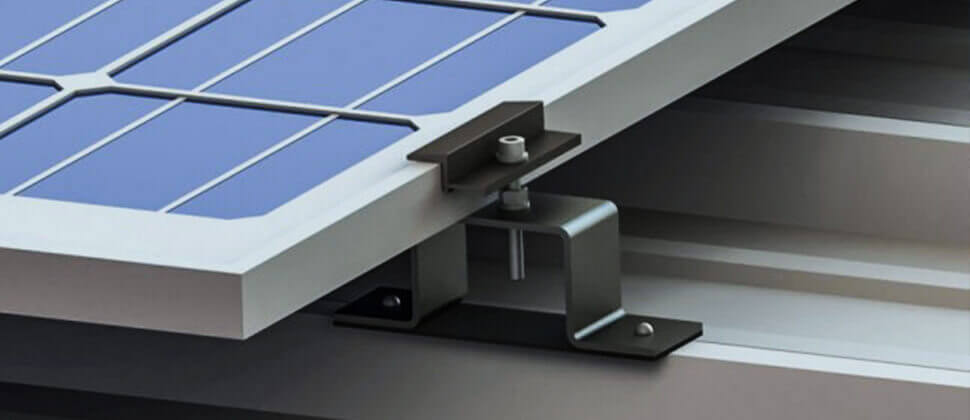

For Standing Seam Profile

One of a kind among metallic rooftop solar mounting solutions is standing seam solution. This non-penetrative approach uses clamps to securely fasten modules in a landscape orientation to the roof. The mounting structure's stability is strengthened by the roof sheet itself, as opposed to other designs that rely on purlins for support.

For KLIP-LOKA Roofs

We have a unique rooftop solar mounting solution for KLIP-LOKA Roofs that stands out in the market. It is the Klip with or without purlins. This non penetrative solution is customisable for any kliplok profile available in the market.